Economic Development Week 2025

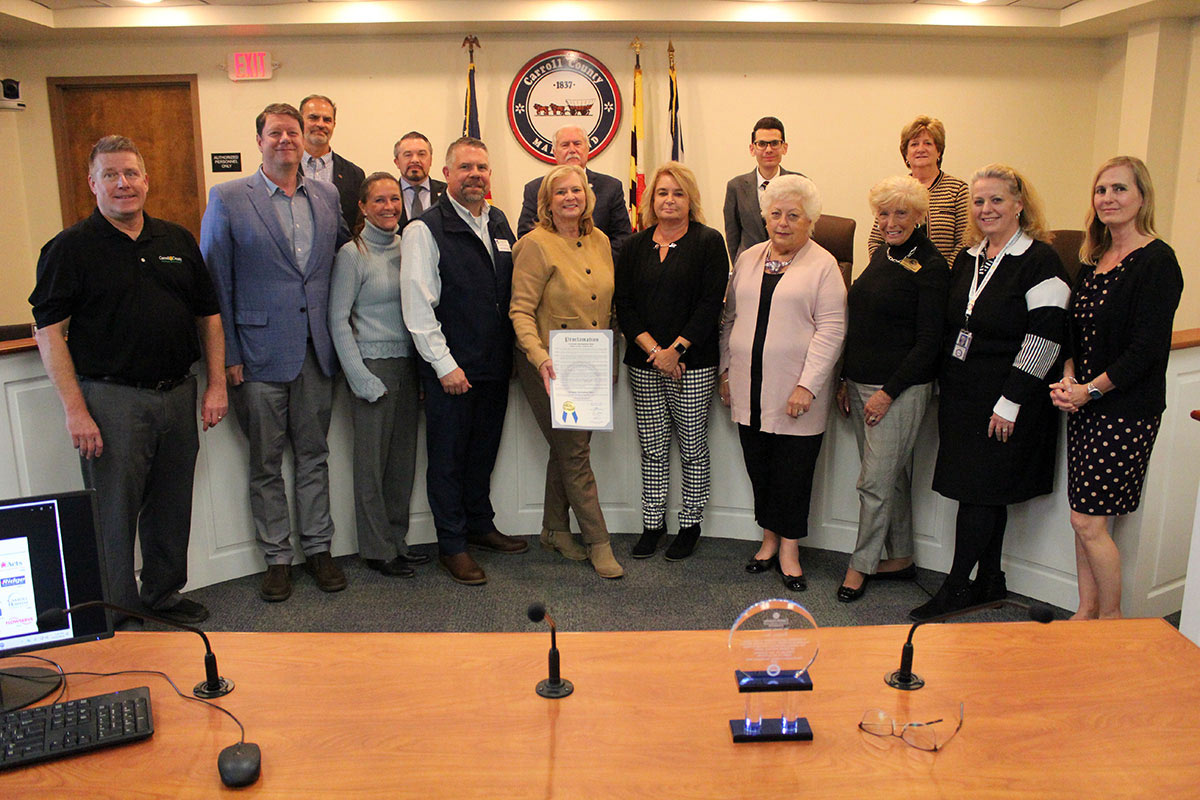

Economic Development Week in Maryland is designed to recognize the unique role that economic development has in creating vibrant communities. For Economic Development Week 2025 (October 20-24), Carroll County will educate, recognize, and promote economic development through a week of engaging action items centered around our four strategic pillars (economic development, agriculture development, workforce development, and tourism development) with visits to long-time businesses in Carroll, business resource information and coordinated social media campaigns.

``NOW, THEREFORE, WE, THE BOARD OF CARROLL COUNTY COMMISSIONERS, do hereby proclaim October 20, 2025, through October 24, 20245 as Economic Development Week in Carroll County, Maryland and ask all to join us in recognizing and reaffirming the importance of business development locally and statewide during this celebration.``

Economic Development Week

October 20-24, 2025

2025 Economic Development Week Photos:

As part of Economic Development Week 2025, the Department of Economic Development was proud to be the Diamond Sponsor of the Carroll County Chamber of Commerce’s Annual Meeting; featuring noted regional economist Dr. Anirban Basu, Chairman & CEO of Sage Policy Group. Image of Councilman Kevin Dayhoff, City of Westminster, Denise Beaver, Director of Econ Dev, Dr. Anirban Basu, Richard Turner, Community Media Center / Chair of Chamber Board and Mike McMullin, President of the Chamber.

Baugher’s Orchard & Farm – 1966

Baugher’s Orchard started out in 1904 as a working farm with an orchard. In 1933, Edward & Romaine Baugher purchased the original 60-acre farm on Baugher Road from Edward’s siblings when his parents died. They expanded their farming efforts, developed improved methods of operating, and survived the Great Depression because of their frugalness and business savvy. They built & opened Baugher’s Restaurant & Fruit Market in 1948 to sell the fruit grown at the orchard directly to customers in Westminster. They tried many different business ventures to add to the limited income that the orchard brought, such as trucking for hire, raising poultry & hogs to sell, making apple butter, making homemade ice cream to serve at the restaurant.

Heidelberg Materials – 1897

Lehigh Cement Company began as a single-mill operation in Ormrod, Pennsylvania, producing Portland cement. As the demand for concrete increased in the early 1900’s, the company thrived. Over the years, a strategy of acquisitions, modernization and increased productivity propelled the company to the position of one of North America’s leading providers of cement and construction materials. 1964 Hanson Trust was formed in 1964 by James Hanson and Gordon White. It rapidly grew by acquisition and became a multinational concern with interests in chemicals, construction, energy, tobacco and other industries. Over the years, Hanson shifted its focus to construction materials and sold its non-core business. By 2006 Hanson had become the world’s largest producer of aggregates. 1977 Heidelberg Cement, one of the world’s leading producers of cement and ready mixed concrete, established a presence in the United States with the acquisition of the Lehigh Cement Company. 2007 Heidelberg Cement acquired Hanson PLC in 2007, creating a multi-national provider of cement, aggregates, ready mixed concrete and other construction materials. 2023 Lehigh Hanson becomes Heidelberg Materials in North America. In 2023 the company united the entire North American family of brands under this new banner while remaining focused on what they do best: heavy building materials. The rebrand reflects a much broader and innovative approach to serving customers and leading the industry in sustainability and digital solutions.

McDaniel College – 1867

Founded in 1867 as Western Maryland College, is a four-year, independent college of the liberal arts and sciences offering over 100 undergraduate and graduate programs. One of the original “Colleges That Change Lives,” McDaniel emphasizes experiential learning and student-faculty collaboration to develop the unique potential in every student. Represented by the Green Terror, over 20 athletic teams compete in the NCAA Division III Centennial Conference. A student-centered community of 1,600 undergraduates and 1,400 graduate students offers access to both Baltimore and Washington, D.C., plus a European campus in Budapest, Hungary.

Performance Foodservice – 1964

Established as Carroll County Foods in 1964, and merged with PFG in 2000. PFG has over 30,000 associates working in more than 150 locations nationwide to deliver more than 300,000 national and branded food products to more than 300,000 customer locations. With one of the nation’s largest truck fleets, they have logged more than 375,000,000 miles. Through a dedication to food safety, a commitment to quality, and strong industry relationships, PFG develops unique brands that set them apart. They develop their own specifications and guidelines for each brand under their umbrella, then work with suppliers to choose the best products for inclusion. PFD also maintains active working relationships with the top industry associations and government agencies, which allows them to stay on the forefront of industry best practices and new technologies.

H&S Bakery – 1994

Ottenberg Bakeries built a corporate office and production facility in Eldersburg in 1994. Ottenberg’s eventually sold their brand and facility to H&S in the 2000’s. H&S Bakery began with “Harry” Tsakalos and Isidore “Steve” Paterakis in 1943 and has been family-owned-and-operated without interruption from day one. Now spanning four generations, the families have remained actively involved in the day-to-day management of the business, providing leadership in various positions across the company, top to bottom. The H&S Family of Bakeries including H&S Bakery, Northeast Foods, and Schmidt Baking Company together make up America’s largest family-owned variety baker, proudly providing specialty baked goods to major industry retailers and small businesses in the United States. Headquartered in Baltimore, Maryland, H&S operates as an integrated network of 10 bakeries and 30 distribution centers located strategically across the Eastern seaboard, not including strategic partners which expands their reach even further.

Penguin Random House – 1967

First opened in 1967 as Random House Operations Center in Westminster, MD. In 2013 Penguin Group and Random House merged into Penguin Random House. The company’s roots date back to the 1800’s and its history in Maryland began in the 1960’s. The Random House imprint was founded in 1927 by Bennett Cerf and Donald Klopfer. The mission, as Cerf put it, was simple, humble, and beautifully open-ended: to publish “a few books, on the side, at random.” Random House would go on to publish more than a few books on the side. In fact, it would publish the first U.S. edition of Ulysses in 1934; become a cherished home to Maya Angelou, Truman Capote, Eudora Welty, Pearl S. Buck, William Faulkner, Edmund Morris, and many others; and publish authors who would win the Nobel Prize, the Pulitzer Prize, and the National Book Award. Today, Random House remains as dedicated as ever to a diverse and far-ranging list of fiction and nonfiction, one that is bound only by their commitment to the highest quality and the size of our authors’ imaginations.

Carroll Lutheran Village – 1980

As one of the first senior living communities in Maryland, Carroll Lutheran Village was founded in 1980 to serve Carroll County seniors’ long-term care needs. What began as a small nursing home has grown into a vibrant life plan community that serves more than 600 residents, providing them with apartments and homes as well as services and amenities that support independence, well-being and a means to build community among neighborly friends. As a non-profit, faith-based organization, Carroll Lutheran Village is guided by a commitment to serve all residents with compassion, respect and integrity. While they welcome individuals of all faiths, the mission is rooted in the values of kindness, empathy, and holistic care. This foundation influences everything they do, from their approach to health care to a welcoming atmosphere that residents and their families have come to love. Carroll Lutheran Village supports residents’ changing needs. With a full continuum of care, residents can seamlessly transfer between different levels of care without ever having to leave the community they call home.

Springfield Hospital Center – 1896

Springfield is a regional psychiatric hospital operated by the State of Maryland, Department of Health and Mental Hygiene, Mental Hygiene Administration. Springfield is accredited by the Joint Commission and is located in Sykesville, Maryland. Springfield Hospital Center was first opened in 1896 and continues to serve the mental health needs of the citizens of the State of Maryland.

Springfield Hospital Center is located on a picturesque campus in southern Carroll County, MD and provides a wide range of clinical services for the treatment of persons with mental illness.

Carroll Hospital / Lifebridge Health – 1961

Carroll Hospital has since grown exponentially, becoming an expansive, state-of-the-art medical center suited to meet the community’s health needs. Carroll Hospital is the heart of its tight-knit community, serving the people of Carroll County for more than five decades. It has grown from a one-building hospital to a true medical center that offers a full complement of care, with specialties including minimally invasive surgery and a state-of-the-art cancer center. The 168-bed nonprofit hospital is known for offering the highest quality care with warmth and compassion. Since joining LifeBridge Health in 2015, Carroll Hospital has expanded in many areas including cardiovascular, women’s health and pediatric outpatient services. Local communities expect and deserve superior medical treatment, compassionate care, and expert guidance in maintaining their health and well-being. Carroll Hospital offers an uncompromising commitment to the highest quality health care experience for people in all stages of life; and are the heart of health care in our communities.

Ridge Engineering – 1970

Founded in 1967 and housed in the most modest of surroundings, with just a few pieces of basic equipment, Ridge has methodically expanded into its own 84,674 square foot manufacturing facility. This dramatic growth could not have been accomplished without the dedication and hard work of dedicated employees. To become what they are today, Ridge has invested heavily in the state-of-the-art technology required to keep up with the ever-changing needs of our customers. That commitment to retain a competitive edge continues each and every year. Their Services include Aluminum Vacuum Brazing, Aluminum Dip Brazing, Precision CNC Machining (High Speed Aluminum, Palletized Production, Small to Very Large, 5 Axis), CNC Turning and Milling, CNC Wire and Ram Electrical Discharge Operations, Precision Laser Cutting. With the recent addition of a second 85,000 square foot building, Ridge now occupies an over 160,000 square foot area.

Shelter Systems – 1976

Shelter Systems has been providing quality wood components to our customers for over 45 years. In 2017, they delivered more trusses than any year in their 45 years of history than ever before. With a regional market extending nearly 250 miles in every direction from their 120,000 square foot facility in Westminster, Maryland, the state-of-the-art facility allows them to provide products to customers at the pace of their building schedule. Products include: roof and open web floor trusses, engineered wood products, and sub-component rough window and door openings. Shelter Systems processes more than 165,000 board feet of lumber daily, or around eight full truckloads between two production shifts. All lumber is stored inside in a climate-controlled manufacturing facility, and they use only the finest kiln-dried, stress rated Southern Yellow Pine. The indoor lumber storage along with the porous, paved finished good yard and the “just in time” promise ensures premium quality building components are delivered to the job site every time. The combination of lean manufacturing processes and a loyal, caring workforce enables them to quickly fill the varied needs of today’s builder with high-quality structural components. From customers initial meeting with staff to the delivery of their product, one can count on each member of the Shelter Systems team to be responsive to the customer’s needs, offer swift reliable solutions, and continue customer service even after the job is complete.

Lippy Brothers Farms – 1965

Lippy Brothers is a family-owned and operated grain and vegetable farming operation in Central Maryland. Ed, Joe, Wilson and Donald Lippy grew up on their parent’s dairy farm working closely with their father. In addition to farming, they graduated from the University of Maryland’s College of Agriculture. In 1951, Ed, Joe and Wilson formed a partnership and began leasing farms on which they grew cash grain and vegetables. They lived off of their wives’ salaries and put every dollar they made back into the company. In 1954, they began purchasing land, and in 1965, along with the fourth and youngest brother, Donald, they incorporated to form Lippy Brothers, Inc. They employed their sister, Betty Horner, to manage the office, which she did for over 40 years. By continuing to buy and lease farms through the years, the company and its owners now own 2,000 acres and leases another 5,500 acres, on which they plant and harvest hay, straw, snap beans, soybeans, corn, and wheat. They have approved conservation and nutrient management plans on all farms, and practice caution and expertise concerning the use of pesticides. Through the USDA Water Quality Cost Share Program, they have installed grass waterways on our fields and enroll in the Maryland Cover Crop program every year. In 1999, Lippy’s placed their first farm into an Ag Preservation Easement and have placed over 2,000 acres in the county and state programs. By selling the building rights to preserve the agriculture land, they have worked to secure a future as a viable agricultural business, employer, and a farm family for future generations. In addition, these decisions support and maintain Carroll County’s heritage as a major agricultural county in both the state of Maryland and the Mid-Atlantic region. In 2001, Lippy Brothers Farms, enrolled in the USDA Conservation Reserve Enhancement Program, which took some of our less profitable land out of production and used it as natural buffers to protect streams from chemical runoff from pesticide application. This improved water quality, reduced soil erosion and expanded wildlife habitat. In 2007 they diversified their grain operation and added a container loading business.

Knorr Brake Company – 1991

Since 1973, Knorr Brake Company (KBC) has been the innovative leader in supplying North American rail market customers, including light rail vehicles, METRO, and high-speed trains. With its North American headquarters in Westminster, Maryland, the company operates sales and service facilities in Carmel, New York; and Union City, California. KBC’s subsidiaries – IFE North America LLC (passenger door systems) and Merak North America LLC (climate-control systems) – are co-located in Westminster. Knorr Brake Company is a member of the Munich, Germany-based Knorr-Bremse Group, the global market leader in braking systems and a leading supplier of other safety-critical rail and commercial vehicle systems. Knorr moved from Baltimore Blvd to new location Arthur Peck Drive in Westminster, MD and held grand opening in 2013. Knorr Brake was located on Baltimore Blvd for 18 years prior to moving to new location Arthur Peck Drive. Knorr’s new $28 million, 235,000-square-foot facility across from the Carroll County Regional Airport is an upgrade from its previous location on Baltimore Blvd. Knorr Brake currently employees over 250 at the Carroll County facility.

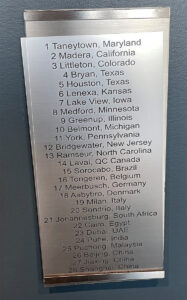

EVAPCO – 1983

EVAPCO, Inc. is an industry leading manufacturing company with global resources and solutions for worldwide heat transfer applications. EVAPCO is dedicated to designing and manufacturing the highest quality products for the evaporative cooling and industrial refrigeration markets around the globe. Their worldwide clients are supported through cutting-edge manufacturing facilities and sales offices strategically located around the world. Headquartered in Taneytown, Maryland, EVAPCO products are engineered and manufactured in 36 locations in 14 countries and supplied through a sales network of more than 200 offices. Founded in 1976 and moving to Carroll County, MD in 1983, EVAPCO’s mission is to provide first-class service and quality products in the following markets: Commercial HVAC, Industrial Process, Power and Industrial Refrigeration. EVAPCO strongly believes in the value of all employees, from the Research and Development engineers and technicians constantly designing new and improved products, to the shop workers who expertly craft each unit and from the receptionists answering the phones to the field technicians refurbishing an old unit. Every step along the way EVAPCO employees add value to the products and services they provide. The culture of ownership gives EVAPCO the drive to go the extra mile, maintaining EVAPCO as a leader in innovative thinking and stellar customer service.

Flowserve – 1971

The multinational corporation traces its roots to the Simpson & Thompson Co., a London pump manufacturer formed in 1790. Flowserve Corporation was formed in July 1997 when two independent flow management companies – BW/IP Inc. and Durco International Inc., merged. The Carroll County facility was built in 1971 as a joint venture between the Weir and Worthington companies, which both produced pumps for industrial customers, said Bjorn Haldorsen, general manager of the Taneytown operation. It was acquired as part of the merger that created Flowserve. Flowserve is a global leader in manufacturing and aftermarket services for comprehensive flow control systems. Flowserve’s expertise enables them to support customers global applications, including energy, water, and food production, as well as other critical infrastructures. What sets them apart is the collective energy of our 16,000 associates across 50 countries and their commitment to always do the right thing. Flowserve provides customers with world-class customer service through localized support, ensuring they receive the best solutions anywhere. They strive to shape a clean energy future by advancing technologies that drive positive global change. By investing in facility Energy Transition and ESG strategies, they can positively impact current and future sustainability efforts to benefit everyone – from customers and associates to the communities in which they operate.

Carroll Community College – 1976

On February 10, 1976, the Carroll County Commissioners entered into a three-year contractual agreement with Catonsville Community College to establish a branch campus in Carroll County. The green light was given for the Carroll County branch of Catonsville Community College to begin its instructional program for more than 750 students with over 1500 course registrations. Consistent growth of the student body, program demands, and future planning resulted in several facility changes, with the College’s first home in the old Robert Moton Elementary School on Center Street. The county, following the recommendation of the advisory board, purchased a site on Route 32. Following this, the East End Elementary School was briefly used for additional classroom space. Then in January 1982, the county made the North Center Street building available to the College. In late 1992, the College met with the Middle States Commission on Higher Education (MSCHE) to become accredited as a two-year, degree-granting institution. After visits by evaluating teams representing MHEC and MSCHE, degree-granting status was offered by MHEC in 1993 and candidacy with MSCHE was awarded later the same year. Carroll was granted full accreditation in 1996. The physical growth of the campus continues to flourish. In 1997, the Random House Library building was built. The Robert Annis and Phyllis Barrett Scott Center for the Fine and Performing Arts, the Business Training Center and Life Fitness buildings were completed in 2002. The Nursing and Allied Health building was completed in 2004. The College’s latest construction project was the K building, an additional classroom building to accommodate the burgeoning growth of the institution. It opened in January, 2010. Carroll Community College has an estimated total enrollment of approximately 3,060 students. The college offers over 40 programs leading to degrees and certificates, including popular fields like Business, Nursing, and Liberal Arts, as well as options for professional skills, job training, and personal enrichment across diverse subjects.

Caldera Manufacturing Group, formerly Fairlawn Tool & Die – 1993

Established in Baltimore in 1954. In 1993 The Baltimore-based company moved its operations to a 42,000-square-foot facility in Hampstead, Maryland, after acquiring a building from the former Snyder Body Inc. In 2018, Fairlawn Tool Inc. built a 75,000 sq ft new facility at the Technology Park in Westminster, MD. Now owned by Caldera Manufacturing as of 2022. Caldera Westminster Facility is a source for superior metal fabrication services on the East Coast and beyond. Since 1954, Fairlawn has been serving customers in a variety of industries, including agricultural, construction, hospitality, media/presentation, military and defense, telecommunications, consumer products and OEM. As an experienced contract manufacturer with a broad range of metal fabrication capabilities, they can provide customers with a single-source solution that reduces lead times and lowers overall project costs.

Northrop Grumman – 1967

Northrop Grumman’s Power & Control Systems (P/CS) in Sykesville, Maryland is a 200,000 square feet site just 30 miles west of Baltimore. Power and Controls touches nearly every system Northrop Grumman develops and it is becoming increasingly more important and integral to achieving system performance as power and energy needs increase and weight/space decrease. Northrop Grumman’s integrated power and energy systems are ideal for supporting current and emerging systems such as electromagnetic sensors, directed energy weapons and radars. Northrop works across sites, business sectors and the industry–collaborating and helping their customers achieve better system performance. Scalable energy storage and management systems are increasingly important for modern naval warfare and Northrop Grumman is leading the way in producing scalable and flexible power storage, management and conditioning solutions using a modular approach to support high-end, power-hungry systems in the future fleet. Core Capabilities…

- Advanced power and electronic control systems

- Engineering and system support through product life cycle

- Manufacturing, Test, Inspection, Quality Assurance, Pack and Ship

- Model and Machine shop for prototyping

- Field / Logistics Support

Acts Fairhaven – 1980

For decades, Fairhaven has stood as a cornerstone of senior living excellence in Sykesville, MD. Today, Acts extends the comprehensive range of Sykesville senior health services to residents and nonresidents alike, embracing anyone seeking assisted living, skilled nursing, memory care, rehabilitation therapy, or respite care. They provide tailored care solutions, ensuring resident needs are met, and should those needs evolve, Acts seamlessly adjust resident care level without disruption. Now a part of ACTS. In the heart of suburban Philadelphia, a pastor and his congregation envisioned a retirement community that would provide a graceful and dignified living experience for seniors. This vision came to life with the establishment of the first Acts community in 1972, now known as Fort Washington Estates, nestled in the picturesque Montgomery County, Pennsylvania. Since its inception, Acts has grown to become one of the premier not-for-profit providers of continuing care retirement communities (CCRCs) in the United States, with 27 communities across nine states along the East Coast. Rooted in a faith-driven mission, Acts is dedicated to serving seniors with integrity and Loving-Kindness, earning a stellar reputation for strength and stability in the senior living sector. Acts employs over 300 in Sykesville.